The welding and metallurgy laboratory tests welds and welded joints using destructive and non-destructive tests.

We are making the following investigations and tests:

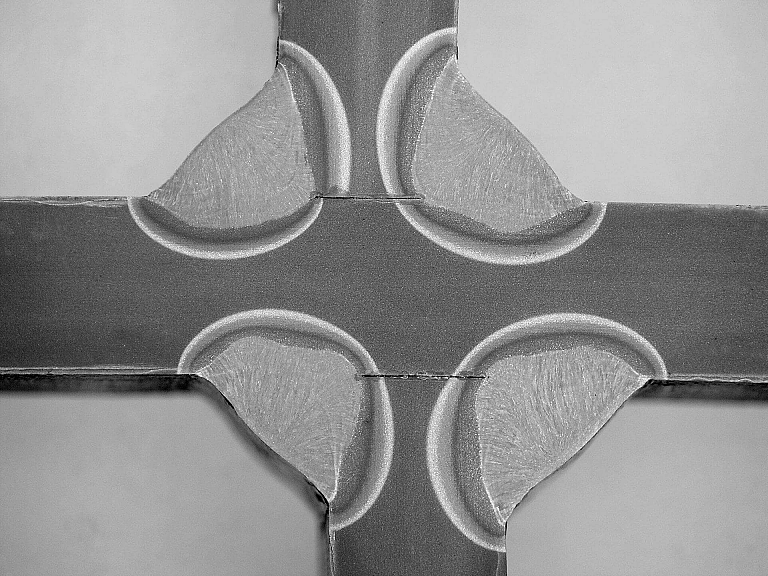

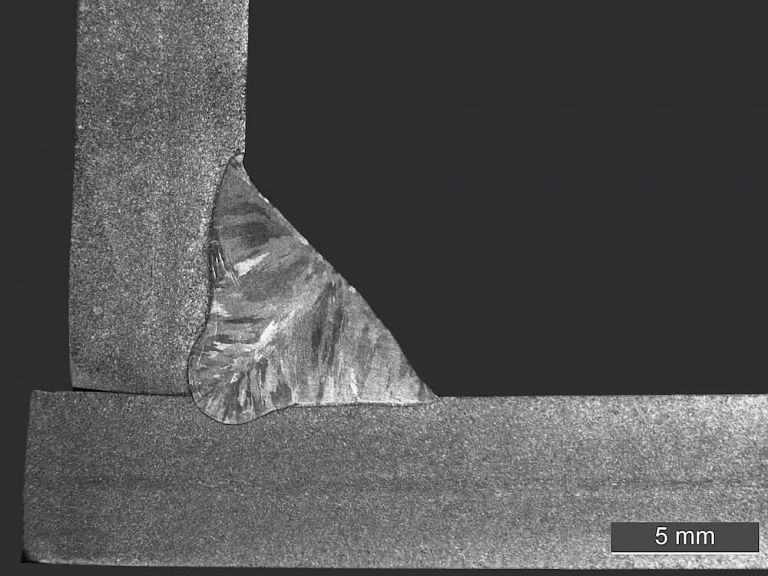

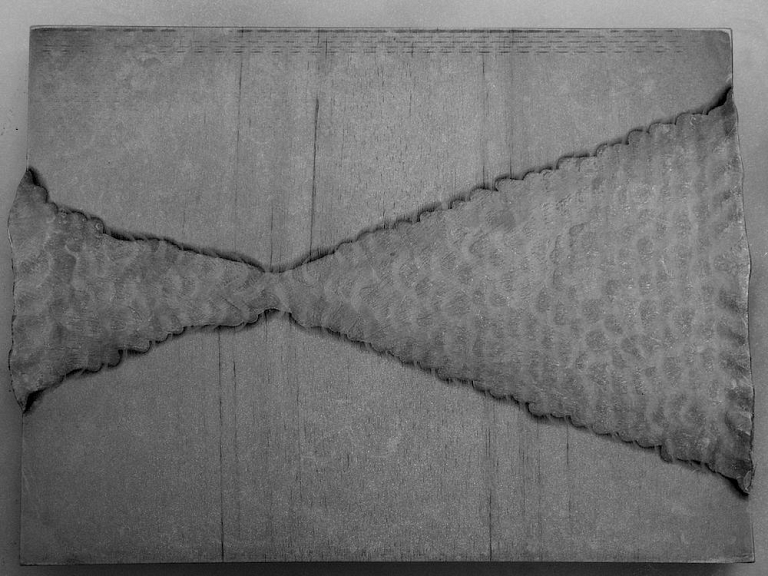

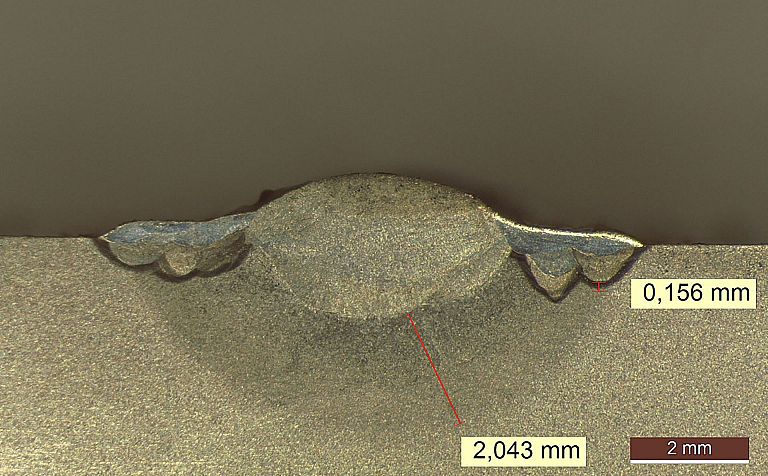

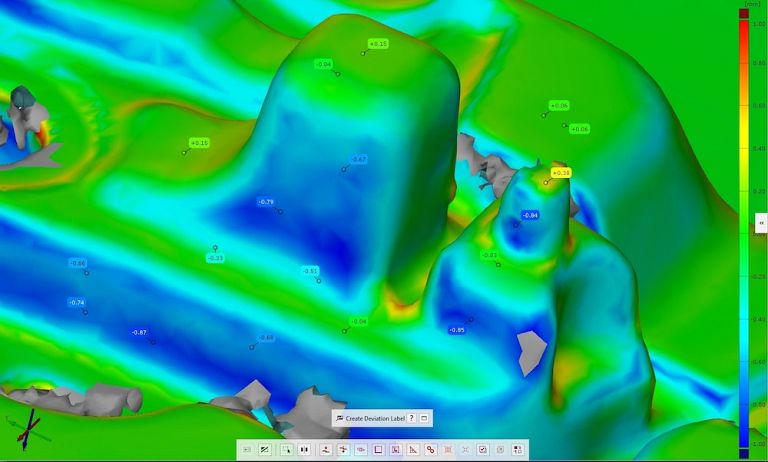

- The macroscopic examination of welds

- Chapry impact tests

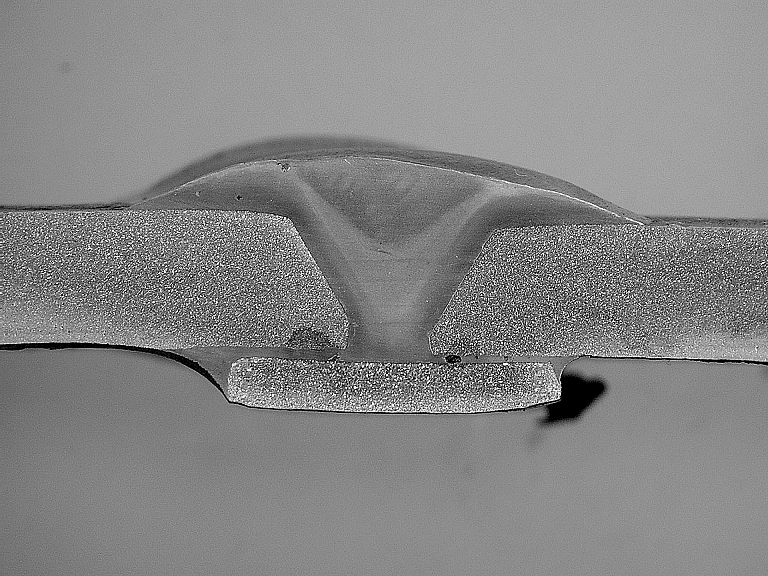

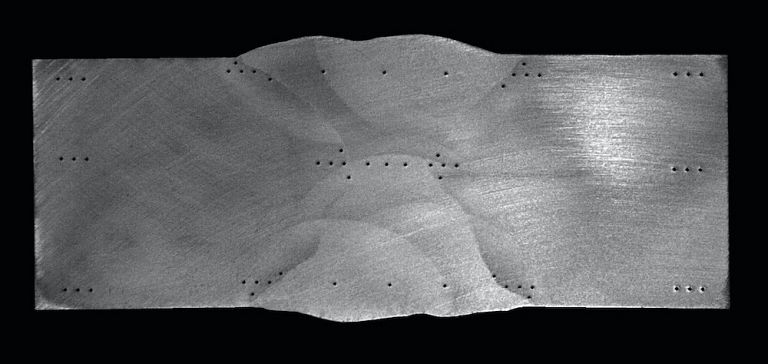

- Band test

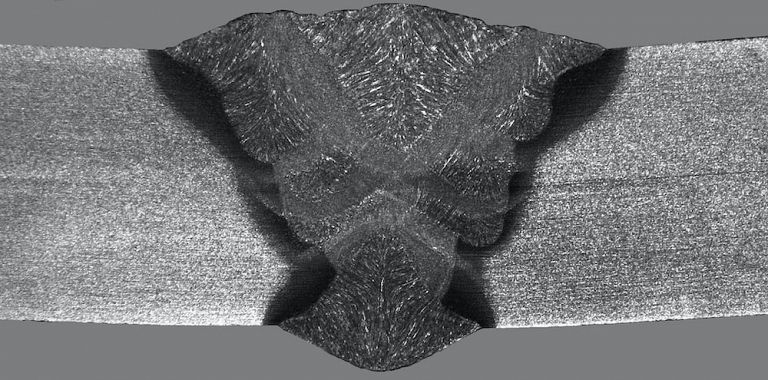

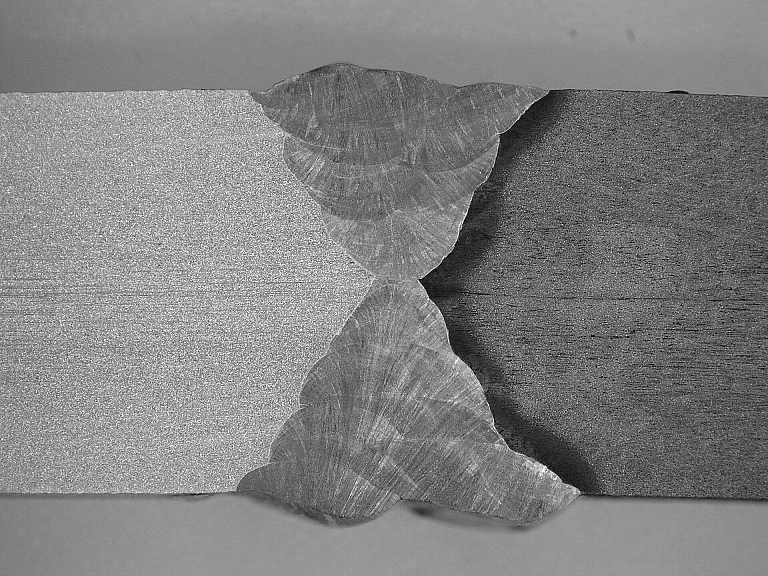

- Fracture test

- Vickers hardness tests

- Transverse tensile tests

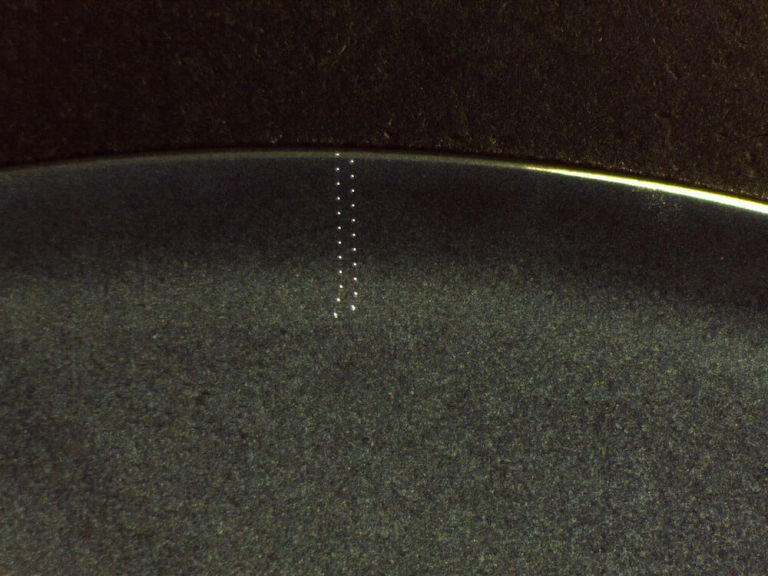

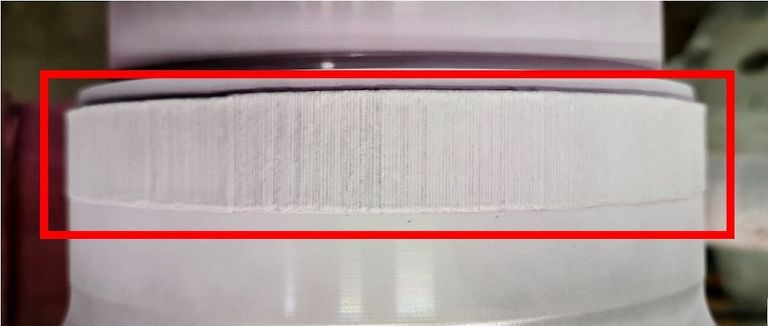

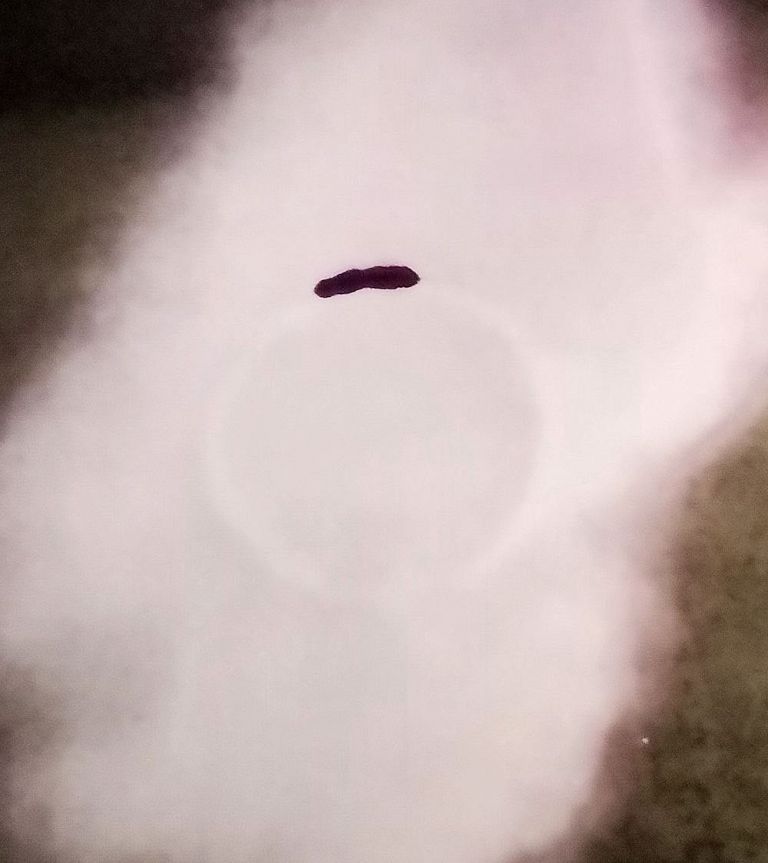

- penetrant tests

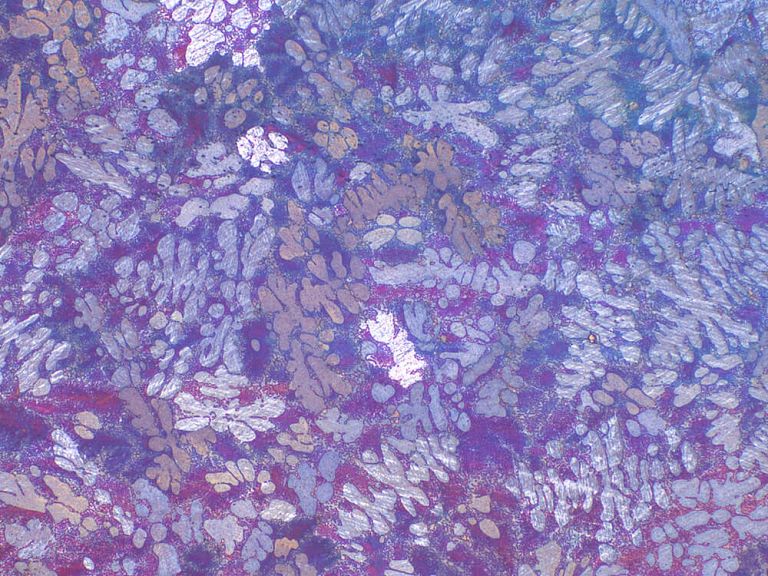

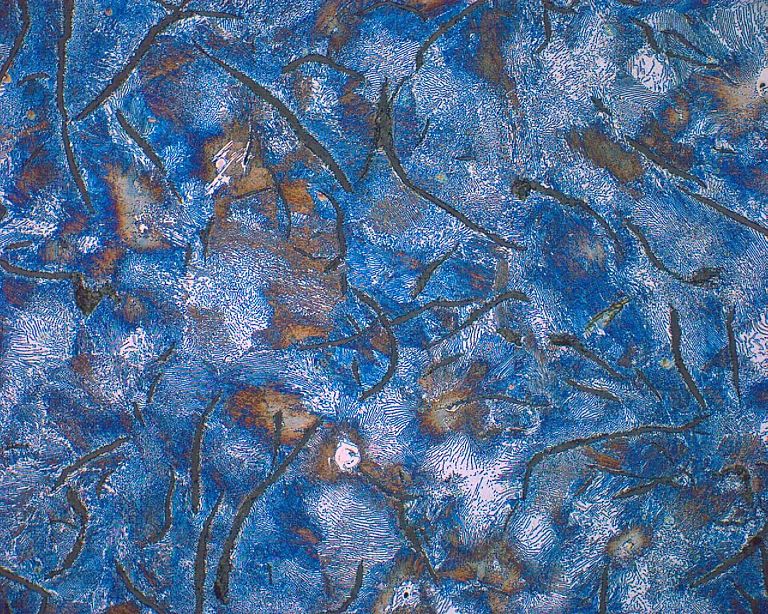

- microscopy (particle size, micro cracking, ferrite share, etc.)

- micro-hardness,

In cooperation with our partners, you can also order various non-destructive tests, chemical analyses of materials, corrosion tests, etc.

Hardness measurements

In the laboratory we perform Vickers hardness measurements. We measure the hardness of metallic materials, check the hardness after heat treatment (quenching, tempering, annealing) and the hardness of welded joints.

We can also perform micro-hardness measurements on request (a non-accredited method).

Hardness measurements are carried out using the Zwick ZHU 2.5 Universal Hardness Tester. Hardness measurements can be carried out from HV0.2 up to HV30.

We also carry out measurements in the field with a portable hardness tester.

Tensile tests

The tensile test is a fundamental mechanical test. It determines the strength properties of metals and alloys, the yield stress (yield strength), the tensile strength and the modulus of elasticity. This numerical data can be directly applied to the strength calculations of various structural elements. Tensile tests are carried out using a Heckert EU40 machine. We are accredited for the transverse tensile testing of base material and welded joints (metallic materials and welds of metallic materials) with the determination of failure force and tensile strength. We prepare the samples for testing ourselves in our laboratory.

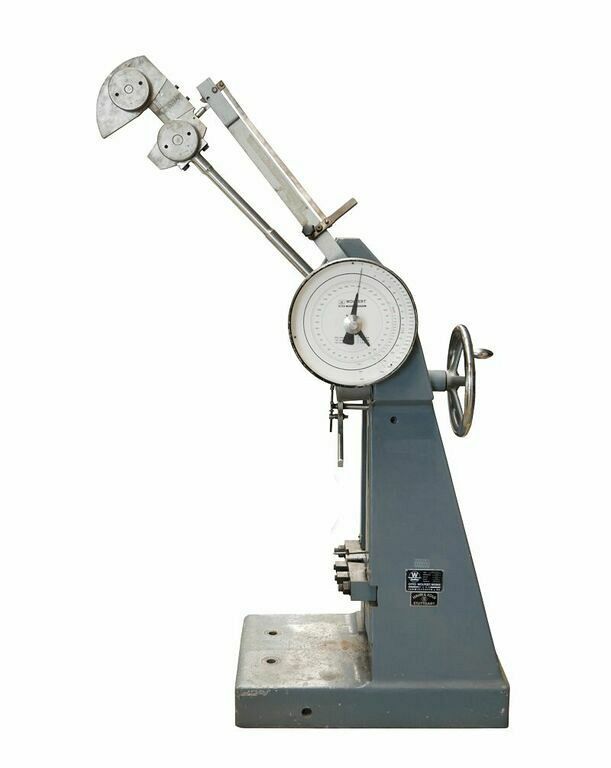

Toughness tests

Toughness is the property of materials before failing after deformation when acted upon by external forces. It is most often related to the impact resistance of the material (impact toughness). Impact toughness is usually measured using the Charpy test. We can test the base material and welded joints in a temperature range of -60°C to +20°C.

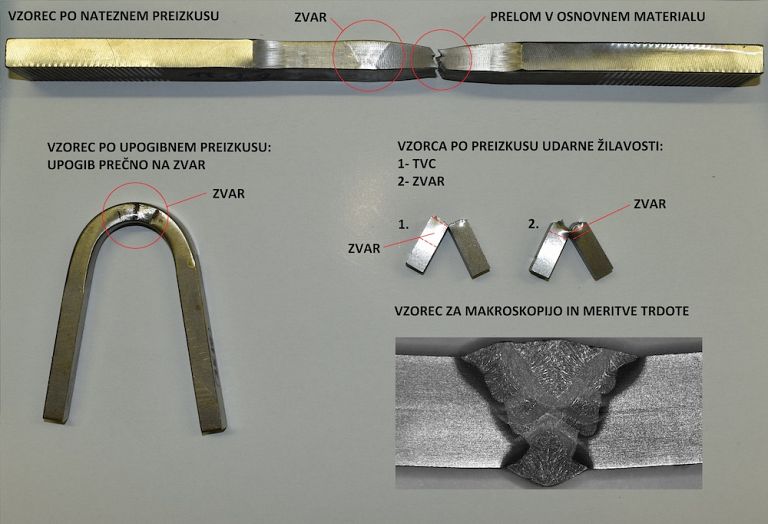

Overview of weld joints

When inspecting welded joints, there is both non-destructive testing (NDT) and destructive testing (DT) available.

Destructive testing includes

To certify the process:

- tensile test

- band test

- impact toughness test

- metallographic testing

- hardness measurement

Depending on the shape of the sample and the quality of the material, certain tests may be excluded from the scope of the tests

For the certification of welders:

- flexural test

- fracture test

- metallographic testing

- tensile test

When inspecting welds and welded joints, we can carry out a penetrant inspection before and after welding, upon request. Since cracks sometimes appear after welding or heat treatment due to material fatigue or the chemical composition of the material, which is difficult to weld, they can be detected and repaired using the penetrant method. However, penetrant testing can also be used prior to welding to pinpoint any cracks, as well as their size and depth.